HVAC Technology has come a long way from the clunky old thermostats. Gone are the days when you must get up and change the temperature in your home or business. All this now happens from your very own smart devices!

Picture this: Seattle’s warm day in mid-July, and you hear your AC system click on. The system quickly satisfies the temperature change within a degree or two of your setpoint, say, 72 degrees F, and the AC system abruptly shut down. Then about fifteen minutes later, the process is repeated until the evening when the outside temperature drops. This is known as short cycling, and over the long term, it uses more energy than necessary through pressure cycling and transient heat loss and can severely impact the lifespan of your compressor.

Most compressors out there are of the fixed-speed type: all or nothing, 0 or 100. This is like having a vehicle that only drives at 70 mph. While it would be great if you lived on a freeway on-ramp, it would not be practical for 90% of your driving scenarios: picking up the kids from school, going on a quick grocery run to PCC, etc. In this analogy, the average cooling or heating demand is an errand within a mile of your home. Instead of repeatedly driving one mile at 70 mph, it would be much more efficient to get there at a reasonable speed and then remain in the vicinity. That is exactly what having an inverter-driven compressor is like.

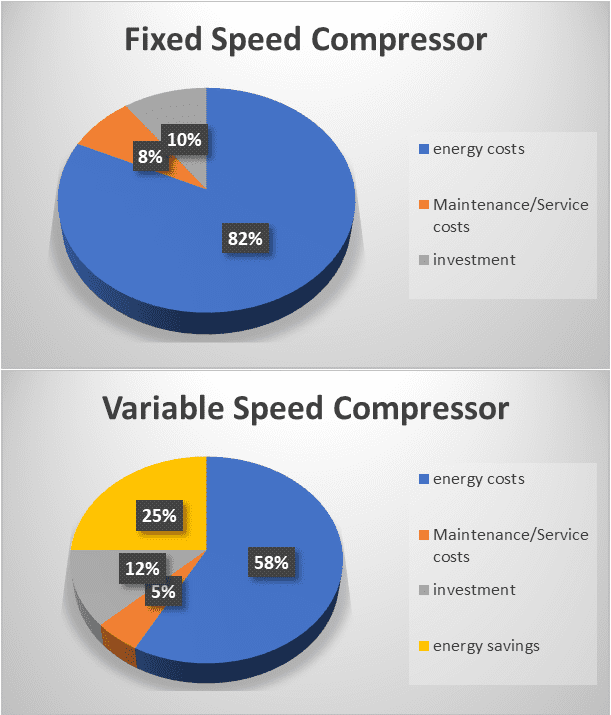

Recently, in the HVAC industry, inverter-driven compressors have become much more commonplace. These innovative designs initiate at around 15% operating capacity and only go to as high as needed to satisfy the demand for heating or cooling. Then the compressor ramps down to a level where it can maintain the temperature and efficiently hovers. Over an extended period, such as a whole cooling season, the ability of the inverter drive to more efficiently modulate cooling capacity can add up in terms of energy costs saved. It also keeps a more consistent temperature in the space. The following chart compares an inverter-driven compressor with a traditional fixed-speed compressor regarding energy costs saved.

Morgan Mechanical can integrate your HVAC system into your existing “smart home” platform, or we can create a digital system for you. Smart Home technology allows you to control settings via a secure connection to your mobile device. You can adapt heating and cooling cycle times to anticipate your arrival home or ensure your pets remain comfortable while you’re away.

We offer proprietary tablet software for apartment building property managers and maintenance crews to troubleshoot most issues. At the first sign of a problem, we can monitor performance diagnostics offsite to expedite service calls and parts orders before a total system failure occurs. Morgan Mechanical is a certified installer of Mitsubishi and Trane comfort systems. We can also repair HVAC units from just about any manufacturer.

Every home is susceptible to indoor air quality issues on occasion. These can exacerbate common respiratory ailments such as asthma and seasonal allergies. I recently read some concerning statistics regarding the quality of the air inside the average home:

“Americans, on average, spend approximately 90 percent of their time indoors, where the concentrations of some pollutants are often 2 to 5 times higher than typical outdoor concentrations.”

People who are often most susceptible to the adverse effects of pollution (e.g., the very young, older adults, people with the cardiovascular or respiratory disease) tend to spend even more time indoors”(Read more here: https://www.epa.gov/report-environment/indoor-air-quality)

We get questions about these sorts of things all the time. The bottom line is this: the in-line filtration that exists on most ducted systems, while beneficial, is not enough to address health concerns like airborne bacteria and viruses (Legionnaire’s disease, etc.), allergens, and other respiratory irritants including mold, dust, smoke, radon, and VOCs. The airborne irritants in the average home are too small to be picked up by the filters on the AC system. While these keep dust out of your ducts, we often say these are for your AC system’s health but not your lungs.

Choose one of the many air cleaner technologies currently on the market to address the minor particulate irritants that are suspended in your home’s air. Let us guide you through an assessment of your home’s indoor air quality and which features you need, and we can make a plan to install a system that can remove the pollutants in the air. Air cleaner technologies include UV light, ionization, or electrostatic means to clear the air. Each has its advantages and limitations. An assessment of your indoor air quality will guide the discussion as to which type of air cleaner is appropriate for your needs.

All homes need adequate ventilation. Does this mean that all houses have it? Not exactly. Based on the occupancy of a space, the idea is to calculate how much humidity will exist in the home and to constantly maintain 30-50% relative humidity and refresh the air inside a space with fresh air from outside. We aim for approximately one air change per hour. This is achieved through whole-house ventilation (also referred to as a whole-house fan).

One such whole-house ventilation system is an ERV or energy-recovery-ventilator. This unit uses a heat exchange device to condition incoming (ventilation) air and serve as means for continuously refreshing the air inside of a space. During the cooling season, the device dehumidifies and removes heat from the outside air as it is brought into the room. During the heating season, the ERV does the opposite: Removing heat and moisture from the exhaust air before blowing it outside and using this to warm and humidify incoming ventilation air.

The average AC unit from just 20 years ago produces 80 or more decibels of sound at the condensing unit (outdoor unit.) Today, that number is down to between 40 and 50 decibels. That’s the equivalent of a polite conversation (think library voice) or a light rain . . . This is a significant improvement, especially considering that the decibel scale is logarithmic, meaning that 40 is not half as loud as 80 but approximately one-eighth as loud. Eighty decibels are on par with a loud vacuum cleaner or dishwasher disposal. Due to some of the other improvements we’ve mentioned, like inverter-driven compressors and quieter fans, the neighbors don’t have to know when you’re AC-unit has come on!

Whether its a residential or commercial project most newer systems use a computer to control the parameters of the system. This provides distinct advantages when a component of your system is failing. Our repair technicians can connect to the equipment and read diagnostic information. A repair technician can diagnose problems and adjust settings remotely with some system controllers. These tools can help reduce the wait time and cost of a diagnostic visit.

A local Northwest-based company that provides residential and commercial HVAC services.

Proudly Serving: King, Snohomish and Skagit Counties.

Copyright @ 2024 – Morgan Mechanical INC

Designed and Developed by MetroMax Solutions