- 425 582 0473

- info@hvacmorgan.com

- 12314 134th Court NE, Bldg A, Redmond, WA 98052

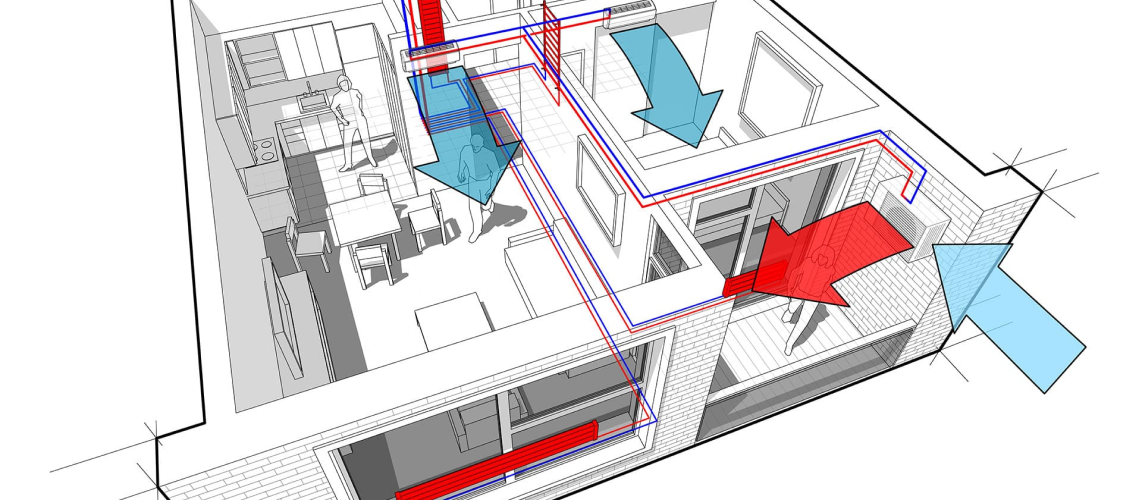

Ductless Heat Pumps, also known as Ductless Mini Split Systems, provide cost-efficient and energy-efficient year-round heating and cooling.

The COVID-19 pandemic brought the issue of indoor air quality into the national conversation, but there are many more reasons to invest in an air purification.

Smart Phones, tablets, and laptops have put the world at our fingertips, including the power to control and customize the operation of the high-efficiency HVAC.

Heating services are a necessity in the Pacific Northwest. Especially as traditionally mild winters are seeing more and more periods of deep freezing.

Cooling Air Conditioning used to be an often-unnecessary luxury in the Pacific Northwest. With Today's high temperatures and sunny skies.

While a furnace generates heat and an air conditioner generates cool air, a heat pump cools or heats the home. Heat pumps primarily move air from sources.

While a furnace generates heat and an air conditioner generates cool air, a heat pump cools or heats the home. Heat pumps primarily move air from sources.

While a furnace generates heat and an air conditioner generates cool air, a heat pump cools or heats the home. Heat pumps primarily move air from sources.

Elevate Your Home Comfort with Our Exclusive Spring-Summer HVAC Maintenance Offer!

Western Washington property owners and businesses trust our reliable and highly-rated system installation. You can count on our expertise in heating, ventilation, and air conditioning. Also, our professionals are versatile in HVAC maintenance, services, and repairs.

In fact, as northwest HVAC professionals, we are committed to helping you get the highest performance from your systems. Also, our expertise in this area allows us to help you pick the right heating and cooling systems. When the time comes to upgrade or replace, we’ll discuss your options – from various manufacturers – so you can make an informed decision.

🔹On average, 6-20 years of qualified service experience per Morgan Mechanical technicians and supervisors.

🔹Industry-leading products in the HVAC industry – dependable & energy – environmentally efficient

🔹We follow up for quality control with professional communication after every install.

🔹1-year warranty of Morgan Mechanical labor – 5 to 10-year system warranty depending on product and manufacturer,

🔹Our team searches for the most cost-effective and durable equipment or part,

🔹Drop cloths, sanitary shoe covering, and clean-up at your home or commercial location.

Dan Dale2023-04-13The experience has always been great. They were persistent until the problem was solved. I would use them again +++

Dan Dale2023-04-13The experience has always been great. They were persistent until the problem was solved. I would use them again +++ Cari Gostic2023-03-21Mike was efficient and knowledgeable, and took the time to answer my questions and show me around the system in my new house.

Cari Gostic2023-03-21Mike was efficient and knowledgeable, and took the time to answer my questions and show me around the system in my new house. Phyllis2023-02-15My service provider was the greatest. Morgan has a very good reputation, and everyone is always so attentive and helpful guy is an individual really appreciate it in a business.

Phyllis2023-02-15My service provider was the greatest. Morgan has a very good reputation, and everyone is always so attentive and helpful guy is an individual really appreciate it in a business. macey chandler2022-12-23I have been working with Morgan Mechanical for about 6 months now and Leena is absolutely great. She always answers the phone, prioritizes my work & is always so genuinely kind. Their techs do a great job & are very cooperative.

macey chandler2022-12-23I have been working with Morgan Mechanical for about 6 months now and Leena is absolutely great. She always answers the phone, prioritizes my work & is always so genuinely kind. Their techs do a great job & are very cooperative. Jerry Cameron2022-11-11It's no fun being without heat on a cold day. Morgan Mechanical was very responsive to my call. The repairman was very confident he'd get the heat pump working in little time and he did. He also checked the system for other potential problems which there weren't. I strongly recommend Morgan Mechanical!

Jerry Cameron2022-11-11It's no fun being without heat on a cold day. Morgan Mechanical was very responsive to my call. The repairman was very confident he'd get the heat pump working in little time and he did. He also checked the system for other potential problems which there weren't. I strongly recommend Morgan Mechanical! Paul Burns2022-07-07As the head of the Facilities Department at Trinity Lutheran Church and Schools, I've had the pleasure to work with Morgan Mechanical on several occasions. Their attention to detail is amazing. They have assembled a great team, starting with real humans that answer your phone calls, to the team that I've personally worked with over the past 3 years: John, Lena, and most importantly the service techs - Matt and Randy - are absolutely top notch. They are prompt, extremely knowledgeable, and they can make repairs or replacement in a short period of time. Morgan's pricing is fantastic, and most importantly, you are never "over-sold." This company is respectable, and I would recommend them as a first choice for any facility that needs expert care and attention.

Paul Burns2022-07-07As the head of the Facilities Department at Trinity Lutheran Church and Schools, I've had the pleasure to work with Morgan Mechanical on several occasions. Their attention to detail is amazing. They have assembled a great team, starting with real humans that answer your phone calls, to the team that I've personally worked with over the past 3 years: John, Lena, and most importantly the service techs - Matt and Randy - are absolutely top notch. They are prompt, extremely knowledgeable, and they can make repairs or replacement in a short period of time. Morgan's pricing is fantastic, and most importantly, you are never "over-sold." This company is respectable, and I would recommend them as a first choice for any facility that needs expert care and attention. Michael Vallidis2022-05-23The Morgan technician acted in a professional manor honoring our no shoe policy, answering my questions as they arose, taking time to explain what to expect in the way of maintnenance that I could perform. Having no prior experience with minisplit systems only whole house heat pumps I was surprised at how little effort the checkup entailed on his part. Are there any other services or features atached to the cost of this visit?

Michael Vallidis2022-05-23The Morgan technician acted in a professional manor honoring our no shoe policy, answering my questions as they arose, taking time to explain what to expect in the way of maintnenance that I could perform. Having no prior experience with minisplit systems only whole house heat pumps I was surprised at how little effort the checkup entailed on his part. Are there any other services or features atached to the cost of this visit? Dr Joel Domingo2021-08-31Called because my furnace motor died in the AM. They were responsive and came same day-- put in a new motor and up and running by the evening. Thanks, Morgan Mechanical!Load moreGoogle rating score: 4.9 of 5, based on 17 reviews

Dr Joel Domingo2021-08-31Called because my furnace motor died in the AM. They were responsive and came same day-- put in a new motor and up and running by the evening. Thanks, Morgan Mechanical!Load moreGoogle rating score: 4.9 of 5, based on 17 reviews

A local Northwest-based company that provides residential and commercial HVAC services.

Proudly Serving: King and Snohomish Counties.

Get updates on special offers and articles!

Copyright @ 2024 – Morgan Mechanical INC

Designed and Developed by MetroMax Solutions